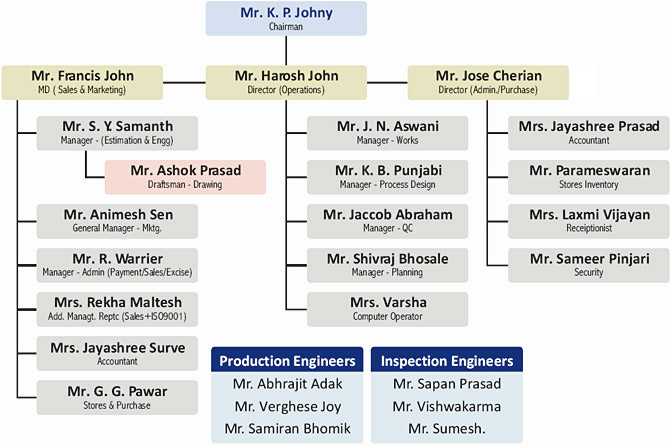

Triofab is a professionally managed engineering and manufacturing company governed by highly qualified professionals. We are very proud of the fact that each and every depar tment of our s is headed by an individual who has outstanding experience in his or her field.

|

We have a strong Engineering team equipped with up to date Codes and Standards along with latest Softwares for the Mechanical Design of Heat Exchangers, Pressure Vessels and columns. The Engineering drawings are prepared by our experienced Engineers / Dr aftsmen who are well conversant with all latest versions of Autocad. We also design special duty/custom built machines and systems as per the specifications and process requirements.

List of Software Used |

Codes and Standards followed |

|||||||||

| Software | Application | |||||||||

|

|

|||||||||

Our procurement department has identified and short-listed the suppliers / Vendors approved by the Engineering Consultants / Surveyors for raw materials & bought-out items. Prior to procurement we take approval of our Vendor List from the client and the concerned Engineering Consultants. The procurement is made considering the factors of Quality, cost and delivery and on basis of our periodic Vendor Rating.

Our manufacturing department is systematically and professionally managed with a well experienced team of technical personnel. Our Works Manager ensures production targets are met. Works Manager is assisted by Production Planning Department which works out the production schedules using tools such as barcharts, PMR etc. Every care is taken to ensure that quality and delivery terms are met. We maintain excellent relations with our labour.

- All Grades of Carbon Steel

- Stainless Steel

- Low Alloy Steel

- High Alloy Steel

- Monel

- Ni Alloy

- Cupro Nikel

- Duplex

Our facility is ASME U-Stamp certified and our Quality control Department headed by Quality Control Manager is responsible for ensuring the quality of raw materials, workmanship and testing used during manufacturing as per Code requirements. All the raw materials are identified and check tested to ensure the quality of the materials. Our Engineers are on vigilance during every stage of manufacturing. Each and every equipment is tested and inspected before shipment.

Our erection team takes care of the erection of the equipment at site and will commission and hand over the same to the clients. Any repairs / Alterations to equipments at Site are done in accordance with the National Board Inspection Code.

You Believe In

You Believe In